Product

Inspection System

AccuVision Inspection System features

- AccuVision inspection systems, with easy to use standard software, are leading the way toward zero defect quality.

- FIS can be used to inspect Nuts,rods,washer fastener,O-ring,special parts.

- Optional cameras are available to check for internal threads and surface imperfections.

- Vision can be added to detect defects like missing internal threads, nylon ring presence, and missing crimp.

- This allows great detail of I.D. threads and the detection of very small defects like; Chips in threads, weld splatter, a single damaged thread, torn threads, reamed threads, short or missing thread(s).

- Windows based software makes part setup easy, and allows for part storage and retrieval.

- Developed software as per indian market requirement

- Run on Very High Speed FPGA based Motion Control Card and other controller

- User Friendly

- External and Internal diameter.

- Pitch and Thread numbers.

- Icomplete processed articles.

- Head crack.

- Head height.

- Broken pin.

- Thread and Slanted thread.

- Pin roundness.

- Length.

Price of the Product

Technical Details

No. of Camera - 4

Vision System - High resolution lanses and light source

Software - Accuvision Pro

Speed - 200 ~ 1000 pcs/min

Operating system - WINDOWS XP/7

Weight - 750 kgs

Accuracy - 0.010mm

Size - 2.1 X 1.4 X 1.9 Meter

Category of the Product

Company website

3

products -

Vision Embesoft Solution

Our recommended products and services

-

-

![TM 2200 TM 2200]()

Tech Measure 2200 based on windows* and a standard computer is a system for intelligent bucking with complete collecting of data. The system will organize the bucking through tree species with a number of presets. The data collection is organized in projects. A thermo printer is used for printing out production figures and machine reports.

-

![TM 3002 TM 3002]()

The TM3006 controller for biomass boilers is designed for the control of small biomass boilers with or without oxygen control.The TM3006 was developed on the basis of the experience from the more advanced biomass controller TM3010 and both in the version with and the version without oxygen control, the TM3006 is an effective controller of small boilers at a very reasonable price.The TM3006 measures the outlet temperature of the boiler water and controls both the blower and the feeder motor to ensure that the temperature required is kept in the system. The blower is regulated without using a frequency converter and the pulse and pause period of the feeder motor is used to regulate the amount of fuel fed into the boiler. The temperature probe included with the TM3006 controller rends the use of the traditional thermostat superfluous and makes it possible to regulate the boiler output from less than 20% up to 100% continuously.A TM3006 equipped with an oxygen probe will constantly measure the level of oxygen in the exhaust gas. Then the controller regulates the blower and the feeder motor in order to reach the best possible combination of oxygen and fuel for the actual boiler performance.The standard TM3006 controller is mounted in a plastic cabinet with a front foil, containing the control buttons and the display. Alternatively, the TM3006 can be delivered as a mounted circuit board and with a foil designed individually to enable each producer to design the TM3006 directly into his biomass boiler system. For further information call Techno-Matic A/S at +45 96987711 or send an e-mail to tm@techno-matic.dk.Product SpecificationsDirect output to feeder motor (3x400VAC) with solid state relays, or alternatively to 1x 230VAC feeder motor, and option between a 1x230VAC refill motor or a 1x230VAC exhaust fanDirect output to blower (230VAC) with solid state relayDirect output to automatic ignition (230VAC)Alarm output (Max. 1A. 24VDC)Input from hot boiler safety switch, which cuts the power to feeder motor and blower (double relay for safe operation)Inputs for security switches (lid open, connection, motor overheat)Input for external start/stopInput for flame control or exhaust temperatureInput for feeding pipe temperature (To minimize the risk of a backburning) or for photo cell (for fuel level, for refill)Controls the outlet temperature of the boiler water, which can be set by the userCan be extended to controlling the oxygen level in the exhaust gasControls start-up procedure with or without automatic ignitionControls pause mode or restart with or without automatic ignitionMenu based display, which shows the actual temperature, the oxygen level, the controller status, and the performance etc.

-

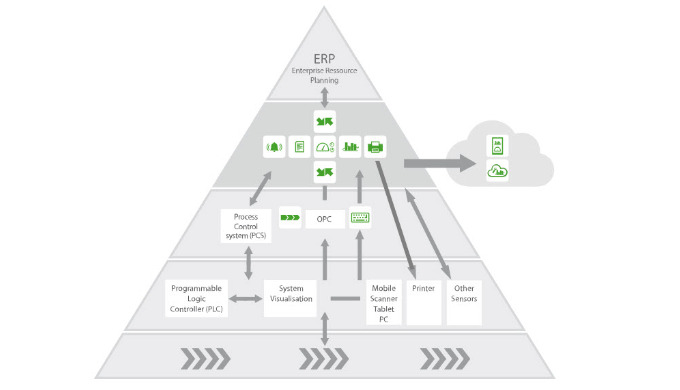

The future of production THE DAWN OF THE SMART FACTORY: New communication models will make it possible for production plants and logistics systems to basically manage themselves in the future. Cyber-physical systems that use the Internet to communicate with each other are used as the technical basis for this endeavour (Internet of Things). The product, for example, introduces its own production information into the manufacturing process in machine-readable form. Based on this data, the path of the product is controlled by the production plants and the individual process steps.

-