Product

Garde-corps en polyester

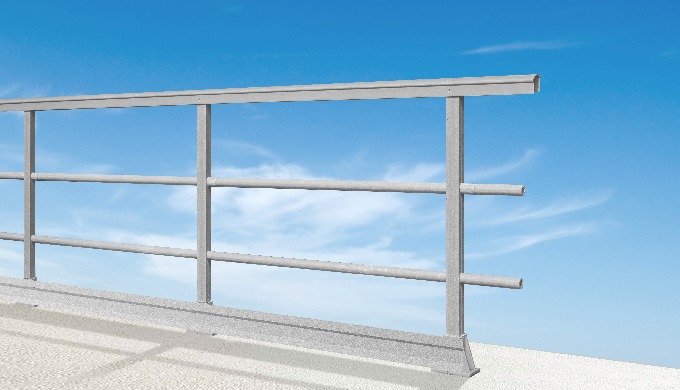

Afin d’assurer la protection des usagers, JK Technic vous propose des profilés pour garde-corps réalisés en résine. Les garde-corps sont principalement utilisés en protection de passerelles industrielles et sont

équipés d’une main courante, d’une ou plusieurs lisses intermédiaires et de poteaux verticaux.

PRESCRIPTIONS DE SÉCURITÉ APPLICABLES AUX GARDE-CORPS

Un garde-corps doit être installé près des zones dangereuses où un risque d’enfoncement ou de passage au travers existe.

Par exemple, une passerelle d’accès à un extracteur sur un toit. Un garde-corps doit être installé dès que la hauteur de chute possible est supérieure à 500 mm.

Un garde-corps doit être fourni lorsque l’espace entre une plateforme et la structure de la machine ou mur est supérieur à 200 mm ou si la protection de la structure n’est pas équivalente à un garde-corps.

Toutefois, une plinthe doit être installée si l’espace séparant la plateforme de la structure adjacente est supérieur à 30 mm. La hauteur minimale du garde-corps doit être de 1100 mm.

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

In addition to manufacturing and installation, we offer a complete maintenance service to ensure the longevity and optimal operation of our products. At Plastical Group, we are committed to providing anti-corrosion plastic boilermaking solutions that guarantee safety and efficiency in your company.

-

Our experience in anti-corrosion plastic boilermaking allows us to offer solutions adapted to a wide variety of industrial sectors, ensuring maximum protection and efficiency in each project for advanced surface treatments in order to improve the physical, chemical and aesthetic properties of your products. We offer turnkey services in installations for electroplating processes. From initial advice to after-sales service, we take care of every stage to ensure that our solutions meet the most diverse industrial needs. We design and install plants with different levels of automation and production capacity, suitable for surface treatment processes

-

At Plastical Group, we specialize in projects for advanced surface treatments such as. Nickel Plating: Improves corrosion resistance and provides a glossy finish. Chrome-plating: Increases surface hardness and wear resistance. Brass: Provides a golden appearance and protects against corrosion. Copper-plating: Improves electrical conductivity and adhesion of other coatings. Cadmium-plated: Offers corrosion protection in marine and aeronautical environments. Anodizing: Increases corrosion and wear resistance in aluminum components. Silver: Improves electrical conductivity and provides a reflective surface. Tin-plating: Protects against oxidation and improves the solderability of electronic components. Zinc plating: Provides a protective barrier against corrosion. ABS Metallized: Improves the appearance and functional properties of ABS plastics. Degreasing: Removes oils and contaminants to prepare surfaces for subsequent treatments. Pickling: Cleans and prepares metal surfaces for further treatment. Phosphating: Improves the adhesion of paints and coatings and offers corrosion protection. Other immersion processes: Adapted to the specific needs of each client. To improve the physical, chemical and aesthetic properties of your products

-