Service

Process Integration

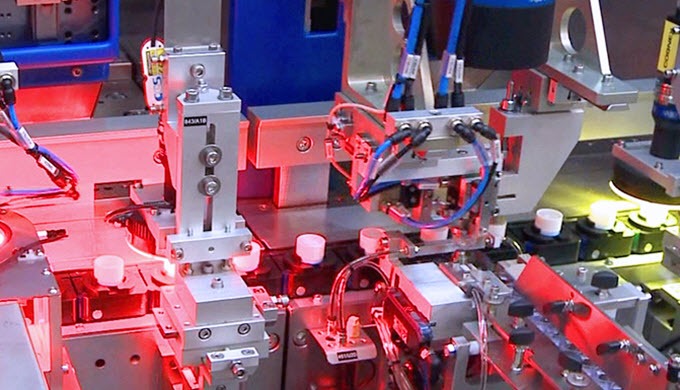

Close to 40 years of process expertise has given Mikron a mastery of very complex assembly and automation tasks. A vast library of standardized processes assure the quality, stability and reliability of your solution. By virtue of our global vision – mastery of the entire operation from the assembly process and the integration of complex processes to the use of a basic range of standardized equipment – our assembly automation solutions are a guarantee of quality, reliability and superior performance standards.

Price of the Service

Technical Details

- Bowl feeding

- Flexible feeding system

- Tray handling

Handling

- Glass handling

- Needle handling and inserting

- Tube handling

Testing and controlling

- Functionality tests

- Flow and leak tests

- Multiple torque tests

- Needle tip, angle, length vision check

- Occlusion check

- Pull check

- Quality tests

- Vision tests

- X-ray checks

Dosing and curing

- Gluing

- Greasing

- Liquid dosing

- Powder dosing

- UV curing

- Thermal curing

Welding

- Laser welding

- Ultrasonic welding

- Resistance welding

Marking and printing

- Hot foil marking

- Inkjet printing

- Labelling

- Laser marking

- Pad printing

Data management

- Data capture

- Line management

- Statistics

- Traceability

Forming and stamping

- Clinching

- Forming

- Hard and soft material stamping

- Riveting

Other specific process

- Coil winding

- Magnetization

- Photovoltaic related process

Category of the Service

Company website

Our recommended products and services

-

-

Autonics Photoelectric Sensors Components commonly used in automation to detect changes in the environment and transmit information electronically. Proximity, photoelectric, fiber optic and pressure sensors, for precise control.

-

Establishing and sustaining profitable production in industries as diverse as medicine and electronics requires continuous production optimisation. Productivity must be improved; energy and resource consumption must be reduced. Development, conversion, and transportation costs must be kept as low as possible so that overall operation costs do not reduce revenue. And perhaps most importantly: Production needs to be safeguarded against disruptions so precious manufacturing time is not wasted.

-

With our load monitors and measurement transducers, we offer a variety of power monitors for your drive technology. The program spans from analog modules for simple applications to processor-controlled units with a large selection of monitoring features and parameters.

-