Product

MES-Systeme

Als Manufacturing Execution System (MES) wird eine prozessnah operierende Ebene eines mehrschichtigen Fertigungsmanagementsystems bezeichnet. Das MES System ist unterhalb der ERP Welt (Enterprise Resource Planning) angesiedelt und zeichnet sich im Gegensatz dazu durch die direkte Anbindung an die verteilten Systeme der Prozessautomatisierung aus und ermöglicht die Führung, Lenkung, Steuerung oder Kontrolle der Produktion in Echtzeit.

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

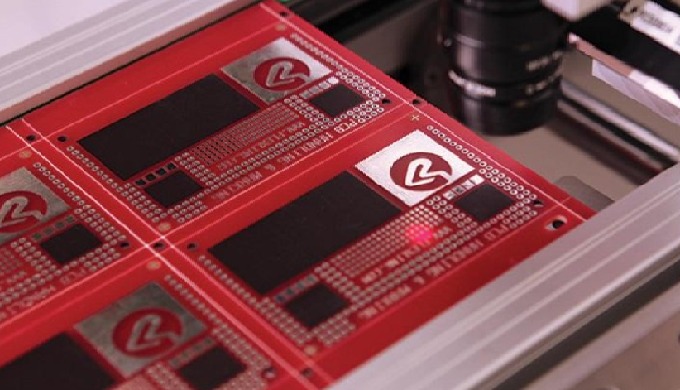

PCB Handling Systems

-

MECHANICAL MODULES In the current debates on the smart factory and Industry 4.0, one can easily get the impression that the advantages of mechanization can only be the result of a radical change. In fact, the opposite is true: more and more design engineers are recognising the potential of mechatronic components and are already using them effectively. This also includes the mechanization of rotational movements. SCHUNK, a leader in clamping technology and gripping systems, has every reason to expand its line of standard gripping system components with respect to electric rotary modules. SCHUNK has the most complete line of mechatronic modules, with more than 300 components as standard, allowing it to offer the right mechatronic rotary module for every dimension, whether it is highly dynamic electronic assemblies, freely positionable rotary divider plates for mounting applications or powerful rotary actuators for heavy loads. SCHUNK has developed the miniature SCHUNK ERD module with endless rotation, the only torque motor with air passages and absolute travel measurement system, especially for assembly applications in the electronics, consumer goods and pharmaceutical industries. The module comes standard with two integrated air passages. The option of four electric steps is also available, as well as the SIL2 certified absolute path measurement system. The SCHUNK ERD module, available in three sizes, with nominal torques of 0.4 Nm, 0.8 Nm and 1.2 Nm, can be used to implement high-torque, high-speed, compact mounting systems in line with the demanding requirements of the machinery directives. The rotary module is driven by a brushless synchronous motor with permanent excitation. Its special geometry ensures high dynamics and acceleration. In addition, thanks to the optimized air passages, the pneumatic actuators connected to the module can be operated more quickly. Both factors combined ensure short cycle times and high productivity. The absolute travel measurement system eliminates the need to waste time on reference runs during start-up and after an emergency stop; It also improves repeat accuracy with a specified value of 0.01 mm. A large number of pole pairs ensures that the module generates a high torque of up to 1.2 Nm even at low revs. The module can be controlled, for example, by using Bosch-Rexroth IndraDrive drive controllers. Contours with minimal interference The versatile SCHUNK ERS rotary module was designed for rotary movements in a medium load range, which is the most requested. The most compact mechatronic rotary module currently available on the market has a height of only 66 mm in size 170. It reaches a nominal torque of 5 Nm and a maximum torque of 17 Nm. This module allows the design of very versatile and compact systems. In mounting applications it can be used as a rotary module or as a rotary divider plate. The main component is a hollow shaft torque, which makes it possible to build a very light and compact module that is completely wear-free and therefore highly effective. With its endless rotation at speeds up to 250 rpm it can reach any intermediate position with a repetition accuracy of 0.01°. Compared to rotary modules equipped with conventional servo motors, the ERS does not have any additional interfering contours. Elasticity of clearance and friction is also eliminated. On the other hand, the resistant module has a high acceleration and rotational speed, as well as high precision. An optional air brake can be integrated to ensure reliable attachment of each position. A large central hole allows the supply of cables or workpieces, as well as the use of a camera. But that's not all. To transport compressed air or signals directly without the use of hoses or cables, the compact module is also available in a version with pneumatic/electrical power steps, in which a slip ring or air duct allows the supply of up to eight electrical signals (24 V DC/2 A) and a liquid with a pressure of up to 8 bar. The SCHUNK ERS module is available in three sizes with outside diameters from 135 to 210 mm. The version with a rotary supply pitch is available in two sizes with outer diameters of 170 to 210 mm. To ensure maximum versatility in the control strategy, the modules can be operated with the SCHUNK ECM motion controller (48 V version) or with a standard regulator, e.g. from Bosch or Siemens (560 V version). Free choice of motors The electric rotary module from SCHUNK ERM also shows the great advantages of using mechatronics in heavy loads. This module combines high torques with high precision. This makes it ideal for variable and precise positioning of heavy loads, such as when turning and reorienting parts in automotive manufacturing. Spontaneous changes in the handling process and constantly changing part types can be easily programmed to increase versatility in process design. This also facilitates commissioning, as ERM modules allow fast and precise adjustment of tolerances during system engineering, which is not possible with pneumatic rotary modules. In addition, it is possible to operate the modules at reduced speed during installation or maintenance, which not only prevents any damage, but also reduces the time needed for the initial boot of the system. The adaptive design of ERM modules allows the use of all standard industrial servo motors. This provides a very high degree of freedom with respect to the control strategy. Equipped with the appropriate engine, the properties of the system controller in terms of programming, fieldbus or safety can be transmitted directly to the module. Offsetting the different regional standards in Europe, the US and Asia is therefore relatively easy. In addition, the auxiliary gearbox, which rotates in steps of 4 x 90°, allows optimal adaptation of the interfering contour of the rotary module and the drive unit for gantry use. A standard central gauge of 22 mm allows a very compact and tidy design of the system. Eight air passages supply compressed air to the pneumatic actuators beyond the rotary shaft. At size 160, the maximum output torque is 75 Nm and the maximum drive torque is 2 Nm. Compact power stations At the higher end of the performance scale, SCHUNK offers three compact and intelligent high-performance rotary modules, optimised for intensive use in industrial applications: SCHUNK PR 2, PDU 2 and PSM 2. In these modules, all regulation and power electronics are fully integrated. This eliminates the need for an external controller and minimizes the number of wired connections as well as the propensity for failure. Power stations are available in three standard sizes. They are controlled via Profibus (up to 12 Mbit/s) or CAN Bus (up to 1 Mbit/s). The modules are equipped with a USB device port for commissioning and parameterization via a PC with the SCHUNK Motion Tool software. Manual addressing is possible via a convenient rotary code switch. The movements of the initial module can be performed manually by using DIP switches. The status is indicated by an LED display. Due to the harmonic drive gears, the PR 2, which is designed as a rotating module, and the PDU 2, designed as a linear shaft module, achieve very high torques, between 16 Nm and 184 Nm, depending on the size. The PSM 2 direct drive is ideal for moving small loads faster. With torque of up to 1.8 Nm, the compact module reaches speeds of up to 4,320 rpm. Individual control of position, speed and torque is possible with all three modules. An incremental encoder ensures high positioning and repetition accuracy. The integrated brake allows reliable maintenance of each position.

-

SCHUNK Gripping Systems – Precision and Performance for Industrial Automation At SCHUNK Intec, S.L.U., we are global leaders in clamping and gripping technology, offering innovative gripping systems designed to improve productivity, precision, and safety in automated manufacturing environments. With decades of experience and a global footprint, SCHUNK provides the world’s most comprehensive portfolio of gripping solutions — from standard pneumatic grippers to intelligent adaptive systems for collaborative robots. 🔧 What Is a Gripping System? A gripping system is a mechanical device used to securely hold, manipulate, and release objects during automated processes. Actuated pneumatically, electrically, or via vacuum or magnetics, these systems are essential for robotic arms, pick-and-place operations, and industrial handling equipment. SCHUNK gripping technology ensures high repeatability, gripping force, and durability, even in challenging environments. Types of gripping systems we offer: Parallel grippers Angular grippers Vacuum gripping systems (suction cups) Adaptive grippers for cobots Quick-change modules Intelligent grippers with integrated sensors (IO-Link, etc.) 🎯 Industrial Applications: Automated part handling in production lines Assembly automation Robotic palletizing and depalletizing High-speed pick & place operations Collaborative robotics (cobots) Industries served: automotive, electronics, food & beverage, pharmaceuticals, logistics, and consumer goods ✅ Benefits of SCHUNK Gripping Systems: Unmatched precision and repeatability Compact, robust design for industrial use High gripping force with minimal energy consumption Long service life and low maintenance Intelligent features: force control, position monitoring, sensor integration Seamless integration with leading robot brands (ABB, FANUC, KUKA, UR, etc.) Local technical support and customization in Spain and across Europe 🔍 Innovation & Custom Engineering SCHUNK doesn’t just deliver standard components — we provide custom-engineered gripping systems tailored to your application. Whether you need a solution for harsh environments, delicate part handling, or high-speed robotic cells, our experts design systems that meet your exact specifications. 📈 Why Choose SCHUNK? Global benchmark in gripping and clamping technology Over 4,000 active product variants German-engineered quality with local technical support End-to-end support: design, integration, training, service Full compatibility with Industry 4.0 automation platforms 📞 Get in Touch with SCHUNK Spain Looking to upgrade your handling efficiency? Let our experts help you select or develop the ideal gripping solution for your application. ➡️ Visit us online: https://schunk.com/en ➡️ Request a quote or technical consultation today

-