Product

Galet combiné AGORA Technique

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

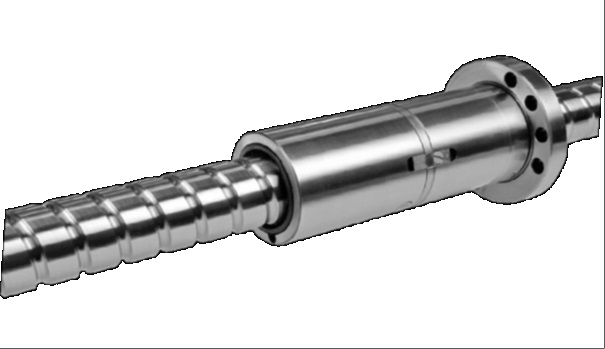

High-load ball screws Compared to standard ball screws, high-load (HL) ball screws are characterized by more than twice higher load capacity and rigidity, achieved by changed radius of the thread profile. In the case of long ball screw shafts, this profile can be ground just in the nut. Short ones (up to three times the length of the nut) always have this profile also on the shaft. High load ball screws have lower efficiency and are designed for slow-running applications. The HL ball screws are usually produced as non-preloaded (single nuts with backlash). In all applications, it is necessary to perform shaft buckling analysis and the nuts must be checked for their flange width in relation to axial load. Characteristics: Precise ball screws for high axial load and long life Thread accuracy of the ball screws complies with the IT1 precision class (DIN 69051) with inter-thread deviation less than 2 μm Shaft ends are ground in the tolerance classes 4 to 6Technical parameters: Recommended shaft diameters are 63, 80, 100 and 125 mm Recommended pitch 20 mm Used material with minimum strength Rm=720MPa Ball screws, surface-induction hardened to 58-60HRC Ball nuts are designed for high loadsConditions for use of HL ball screws: Transmission efficiency approximately 0.93 – 0.95% Shaft buckling analysis is necessary Lubricants for high loads must be used. Recommended lubricants are: Klüber Microlube GL 261, OKS 400, Optimol Longtime PD 2, Lubcon Turmogrease PHS 1002 (all other greases suitable for high loads). Working temperature up to 90°CApplications: Injection moulding machines Transportation mechanisms Lifting equipment Replacement for hydraulic cylinders Example of designation: K80×20 – 4/AP HL/3 (ball screw with diameter 80 mm and pitch 20 mm, 4 working threads, single nut with flange, high-load design, flange type 3) High-load ball screws : www.ks-kurim.cz/en/ball-screws/high-load-ball-screws/

-

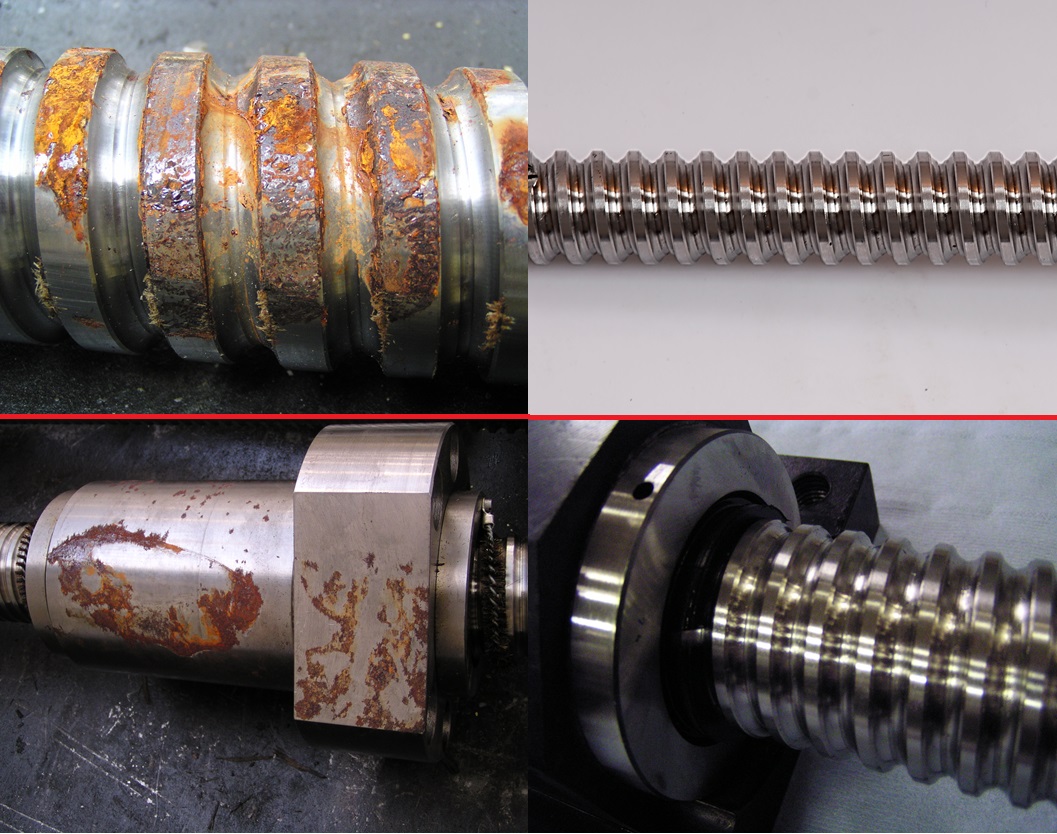

Repair and services The company KULIČKOVÉ ŠROUBY KUŘIM, a.s. provides repairs and overhaul of ball screws from its own production program and such produced by foreign ball screw producers. Those repairs are exclusively done in the company’s premises, where precise measurement and evaluation of the condition of the ball screws is being provided, thus offering an optimal solution for the customer. We offer also full-value replacement of the worn, unreparable ball screws, manufactured by any ball screw producer, with ball screws newly produced in our company. KSK offers: Overhaul an repairs of ball and trapezoidal screws manufactured by our company Overhaul an repairs of ball and trapezoidal screws manufactured by other producers Functionality renovation and preload setting, alternatively backlash reduction of the nut Full value replacement of worn screws with new ones, produced on basis of delivered sample Emergency repairs of ball and trapezoidal screws in short terms Repair and services : www.ks-kurim.cz/en/services/repair-and-services/

-

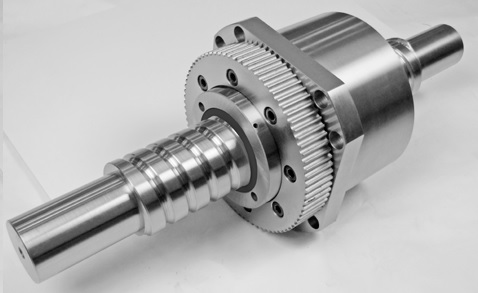

High-speed ball screws New technologies bring essential changes in the requirements for machine tools especially concerning rotational speed of the working spindle (up to 50,000 rpm), spindle output (15÷60 kW), linear working speed (10÷30 m.min-1) and linear high-speed (40÷80 m.min-1). In order to achieve the above mentioned parameters engineers are forced to use linear motors or high-speed ball screws. The linear motors have high cost and their high electromagnetic field often causes complications for the machine tool builders. This is why the cheaper and technically sufficient high-speed ball screws are more widely spread. In them the thread pitch P equals their diameter Do and they can be run at high rotational speeds n (Do multiplied by n can be up to 125,000). For this type of ball screws the following nut types are available: Single preloaded nuts by difference between thread leads Nuts with patented external ball recirculation system Usually nuts with flangeCharacteristics: Precise ground positioning screws High pitches up to the size equal to their nominal diameter, two-start and four-start screws Standard geometric and working accuracy, service life and load capacities according to DIN ISO 3408 Delivered with customized preloadTechnical parameters: Diameters from 16 to 50 mm Pitches from 15 to 50 mm, thread lengths to 2 m Thread lengths over 2 m can be supplied in single-start design with segments Accuracy class IT1 and IT3 Do×n = 125,000, efficiency 94–97% (according to thread pitch and lubricant) Minimum strength of the shaft material Rm= 650MPa, functional surfaces of the shaft and nut hardened to 58-60HRC Working temperature -40 to +80°C (according to lubricant type) Lubricants with high viscosity are recommendedApplications: Machine tools Positioning mechanisms Example of designation: K40×40 – 1.5+1.5/APVR HS/3 (ball screw with diameter 40 mm, with right hand two-start pitch 40 mm, with 1.5 working threads, preloaded nut type APVR with flange type 3) High-speed ball screws : www.ks-kurim.cz/en/ball-screws/high-speed-ball-screws/

-